MS27039 : Mil-Spec Hardware

MS27039 : Mil-Spec Hardware Specification

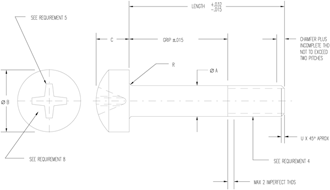

SCREW, MACHINE - PAN HEAD, STRUCTURAL,

CROSS RECESSED

Click on drawing for larger view Click on drawing for larger view

REQUIREMENTS:

NOTES:

- 1. All dimensions are in inches.

- 2. Screws shall be free from burrs and sharp edges.

- 3. Dimensions are to be met after plating.

- 4. Shank diameter may be .001 oversize for a maximum distance of .031 adjacent to the head.

- 5. In the event a conflict between the text of this document and the references cited herein, the text of

- this document will take precedence.

- 6. Unless otherwise specified, issues of referenced documents are those in effect at the time of solicitation.

- 7. Caution should be taken during plating process. The contractor shall be responsible for the safe

- reutilization and disposal of all materials generated by this process in accordance with ASTM A380,

- section 8.2 and 8.7.

- 8. Items manufactured to Rev. C and Rev. D may be delivered from suppliers stock until depletion.

REQUIREMENTS:

1. MATERIAL:

- Aluminum Alloy 2024 (UNS A92024) in accordance with QQ-A-430, Temper 2024-D, or

QQ-A-225/6, Temper T4.

- Manganese Bronze (UNS C67000) in accordance with ASTM B138.

- Alloy Steel 8630 (UNS G86300) in accordance with MIL-S-7839, 26-32 HRC or 8740

(UNS G87400), 4130 (UNS G41300) in accordance with MIL-S-6049.

- Heat and Corrosion-Resistant Steel, A286 Iron Base Super Alloy (UNS S66286) in

accordance with AMS 5731 or AMS 5732.

2. PROTECTIVE COATING AND SURFACE TREATMENT:

- Aluminum Alloy: Anodize, in accordance with MIL-A-8625, Type I or II.

- Manganese Bronze: Cadmium Plate, in accordance with QQ-P-416, Type II, Class 3.

- Manganese Bronze: uncoated.

- Alloy Steel: Cadmium Plate, in accordance with QQ-P-416, Type II, Class 2.

- Heat and Corrosion-Resistant Steel: Passivate in accordance with QQ-P-35 after removal

of all oil and grease. Passivation verification test per Method 102 of MIL-STD-753.

3. TENSILE STRENGTH:

- Aluminum Alloy: 62,000 psi min ultimate tensile strength.

- Manganese Bronze: 85,000 psi min ultimate tensile strength.

- Alloy Steel: 125,000 to 145,000 psi ultimate tensile strength.

- Heat and Corrosion-Resistant Steel: 130,000 psi min ultimate tensile strength.

4. THREADS:

Threads shall be accordance with FED-STD-H28/2. Acceptability of screw threads shall

be in accordance with FED-STD-H28/20, system 21.

5. RECESS:

The recess shall be in accordance with MS9006.

6. MATERIAL AND FINISH CODE:

- Add DD before dash number for Anodized Aluminum Alloy Screw.

- Add BP before dash number for Cadmium Plated Manganese Screw.

- Add B before dash number for uncoated Manganese Bronze Screw.

- Add - before dash number for Cadmium Plated Alloy Steel Screw.

- Add C before dash number for Heat and Corrosion-Resistant Steel Screw.

7. PART NUMBER:

The part number shall consist of the basic MS number followed by the material and finish code

followed by the dash number.

- Example: MS27039DD0809 indicates - Screw, Machine - Pan Head Structural, Cross Recessed;

.164-32 UNC-3A, .594 length, Anodized Aluminum

Alloy Screw.

- MS27039BP 0809 indicates - Screw, Machine - Pan Head Structural, Cross Recessed;

.164-32 UNC-3A, .594 length, Cadmium Plated

Manganese Screw.

- MS27039B0809 indicates - Screw, Machine - Pan Head Structural, Cross Recessed;

.164-32 UNC-3A, .594 length, uncoated Manganese

Bronze Screw.

- MS27039 - 0809 indicates - Screw, Machine - Pan Head Structural, Cross Recessed;

.164-32 UNC-3A, .594 length, Cadmium Plated Alloy

Steel Screw.

- MS27039C0809 indicates - Screw, Machine - Pan Head Structural, Cross Recessed;

.164-32 UNC-3A, .594 length, Heat and Corrosion-

Resistant Steel Screw.

8. HEAD MARKING:

- a. Basic part no. and applicable dash no. (Basic part optional for .164-32 screw sizes).

- b. Material as follows: Aluminum Alloy - none, Bronze - “B”, Alloy Steel - “-”, Heat and Corrosion - Resistant Steel -”C”.

- c. Manufacturer’s trade-mark shall be added, location optional.

Need the Spec?

Click here to download MS27039 Specification

(PDF Format).

|